News

Knowledge of alloy saw blade welding teeth

Welding Tips

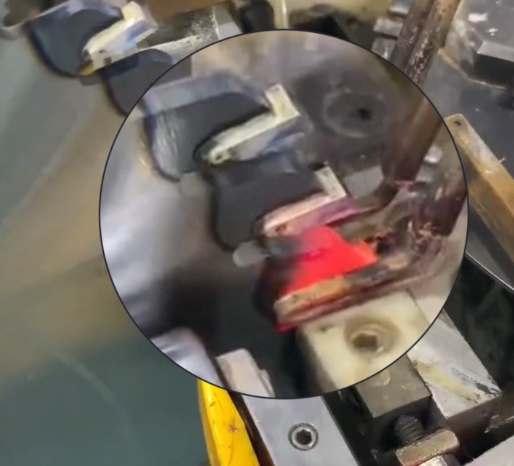

The alloy is sintered from ultrafine powder under high pressure at a temperature of 1200℃. Currently, alloy welding tends to be done at low temperatures. The aim is to protect the metallographic structure from damage during welding. The welding temperature should not exceed 750℃, and uniform temperature is best achieved through inter-tooth welding. When welding teeth, pay attention to the presence of carbides in the alloy, keep the alloy clean, and ensure the surrounding area is free of dust or maintain a constant workshop temperature. The tooth base must not have rust spots or oxides. The flux should not be too concentrated or too diluted; it should be mixed into a paste. Granular flux should not be used. Prevent sedimentation; when reusing flux, it should be mixed and preferably dripped onto the alloy, not smeared onto the base material or outside the tooth root. When using silver solder wire, do not pursue excessively high silver content; generally, 45% is sufficient. The main metallic elements in silver solder wire are silver, copper, and nickel. Silver is used at low temperatures, nickel and zinc enhance fluidity, and copper increases strength. Adding appropriate amounts of manganese, indium, and selenium further strengthens the bonding force. Manganese is porous, and indium and selenium are too expensive. Generally, the welding strength of welding wire is 5-16 kg per square centimeter. The strength of each tooth depends on the size of the alloy welding area, but it should not be less than 50 kg, and for industrial types, it should be above 100 kg. After welding the saw blade, it should be immediately placed in a 100℃ oven for tempering to reduce stress caused by the weld and refine the internal structure of the alloy, thereby improving durability and wear resistance.

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lily Tang

Tel: 0086 13812228944

E-mail: info@baolisaw.com

Add: Jinglin Industrial Park ,Jinling East Road ,Danyang City,Jiangsu Province, China

English

English Pусский

Pусский Lily Tang

Lily Tang