News

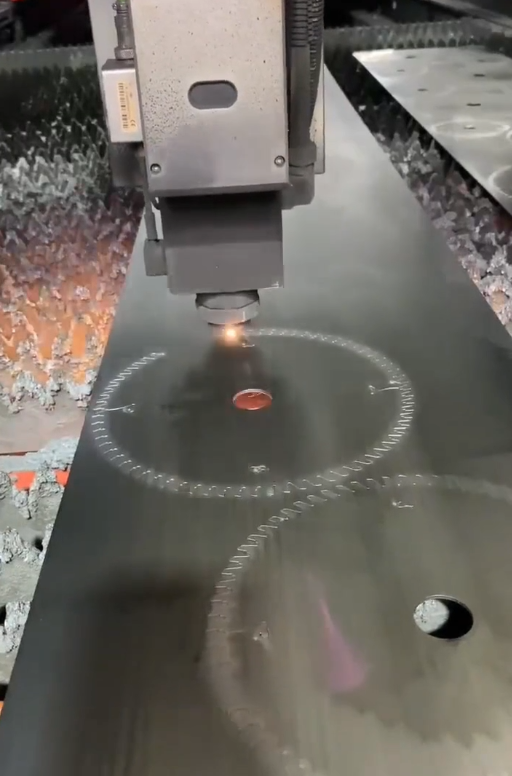

Saw blade processing knowledge

There are many types of saws, but the vast majority consist of a saw blade and serrations along its edges. Saws are basically classified into two main categories: disc saws and strip (band) saws. Their dimensional parameters are expressed by thickness and width, length, or diameter. The part that directly cuts the wood during sawing is the saw tooth.

Saw teeth are mainly classified into longitudinal cutting teeth and transverse cutting teeth according to their orientation relative to the wood fibers when cutting wood. Based on the grinding method, saw teeth are further classified into straight-ground teeth and oblique-ground teeth. Longitudinal cutting teeth are mostly straight-ground, while transverse cutting teeth are primarily oblique-ground.

The main angles of the saw teeth are:

Rake angle g: The angle between the line passing through the tooth tip and perpendicular to the line connecting the tooth tip (base plane line) and the front face line of the saw tooth. In the diagram, the rake angle measured clockwise from the vertical plane passing through the tooth tip or the radial line of the saw blade towards the front tooth face is defined as "+".

Back angle α: The angle between the back line (or tangent to the back line) of the saw tooth and the tip line (or tangent to the tip line). The back angle of a circular saw blade is the angle between the tangent to the tip circle of the tooth and the back tooth surface. If the back tooth surface is an arc surface, then the tangent to the arc-shaped back tooth surface passing through the tip is taken as the back tooth surface.

Wedge angle b: is the angle between the front tooth surface and the back tooth surface.

Saw cutting is mainly divided into pressing and releasing. Straight-tooth grinding primarily presses material, while oblique-tooth grinding is only for releasing. The amount of material sawn is expressed by the width and angle of the saw cut.

2. Cutting of the saw teeth

1) Cutting of longitudinal saw teeth

Sawing differs from right-angle free cutting. In sawing, the saw teeth cut the wood with three cutting edges, completing three cutting surfaces in one stroke – the bottom of the kerf and the two side kerf walls. Timber slitting refers to sawing where the feed direction (kerf direction) is parallel to the grain direction, such as the splitting of band saws and circular saws.

2) Cutting of the transverse saw teeth

When cross-cutting, the feed direction (or kerf direction) is perpendicular to the fiber plane, as in the case of a circular saw. If a cross-cutting saw with a cutting angle greater than 90° is used to cut the wood, the initial cutting of the teeth is similar to making a knife cut into the wood. Adjacent teeth successively cut two parallel tooth marks on the wood surface. As the teeth penetrate deeper into the wood, the component of the resultant force of the front teeth acting on the wood in the kerf direction perpendicular to the kerf compresses the wood in the middle of the kerf that has already been cut on both sides, causing it to shear along the grain direction at the bottom of the kerf. When the depth of the saw teeth into the wood is large enough, the component of the force perpendicular to the kerf direction exceeds the shear limit of the wood along the grain, and this part of the wood in the kerf is damaged.

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lily Tang

Tel: 0086 13812228944

E-mail: info@baolisaw.com

Add: Jinglin Industrial Park ,Jinling East Road ,Danyang City,Jiangsu Province, China

English

English Pусский

Pусский Lily Tang

Lily Tang