Grinding outer diameter:Φ180-Φ650

Grinding tooth pitch:T1.3-T22mm

Grinding wheel outer diameter:Φ200mm

Grinding wheel inner diameter:Φ32mm

FNC-500 650 Series Fully Automatic Gear Grinding

|

Equipment function parameters |

|||

|

NO |

Function |

FNC-650 |

FNC-500 |

|

1 |

Grinding outer diameter |

Φ180-Φ650 |

Φ130-500 |

|

2 |

Grinding tooth pitch |

T1.3-T22mm |

T1.3-T22mm |

|

3 |

Number of grinding teeth |

20-600 |

20-600 |

|

4 |

Saw blade thickness |

5mm (thickest) |

5 mm ( most thick ) |

|

5 |

Grinding wheel outer diameter |

Φ200mm |

Φ200mm |

|

6 |

Grinding wheel inner diameter |

Φ32mm |

Φ32mm |

|

7 |

Grinding tooth type |

Triangular teeth/ arc teeth/high and low teeth/slotted teeth |

Triangular teeth, arc teeth, high and low teeth |

|

8 |

Grinding wheel motor |

5.5kw |

5.5kw |

|

9 |

High-pressure coolant device |

0.55kw |

0.55kw |

|

10 |

Total power used |

10.5kw |

10.5kw |

|

11 |

Normal operating electricity |

2.3 kw -hour |

2.3 kw -hour |

|

12 |

Machine net weight |

1300kg |

1100kg |

|

13 |

Machine size |

1300×1500×1900mm |

1100×1400×1800mm |

|

Without Chamfer No chamfe

|

I3 1- |

Arc teeth and arc teeth left and right chamfers, used for cutting thin-walled metal pipes, with chamfers at intervals of one-third on the left and right |

|

Chamfer Chamfer |

|

Chamfer fall horn

Four 7 Asia

Arc high and low teeth, used for cutting thick-walled metal pipes, One-third chamfer on both sides of the teeth

Without one Chamfer

No chamfer

|-

33-5

Triangular teeth and triangular tooth chamfers, used for general slot milling

and soft metal cutting

th Form slotted teeth

—13331—

BR Four

The tooth grooves are good for heat dissipation and chip separation; the cut is more Smooth, mostly used for online high-speed cutting

C-type teeth

Chamfer Chamfer

Accessories are constantly updated without prior notice.

BR/grooved teeth

Tooth grinding + slotting + chamfering grinding completed in one go

One-time setting completes all automatic grinding from tooth profile to chamfering and grooving, without Any adjustments that require downtime

Grinding wheel spindle speed can be set arbitrarily

According to the characteristics of different grinding wheel saw blades, different speeds can be set arbitrarily

High-precision grinding/arbitrary angle adjustment

The angle parameters of the front and back angles can be input arbitrarily, and the machine will automatically offset the Position, no manual adjustment required, front angle ±1.0°, back angle ±1.0°, tooth depth ±0.1mm,R±0.1mm

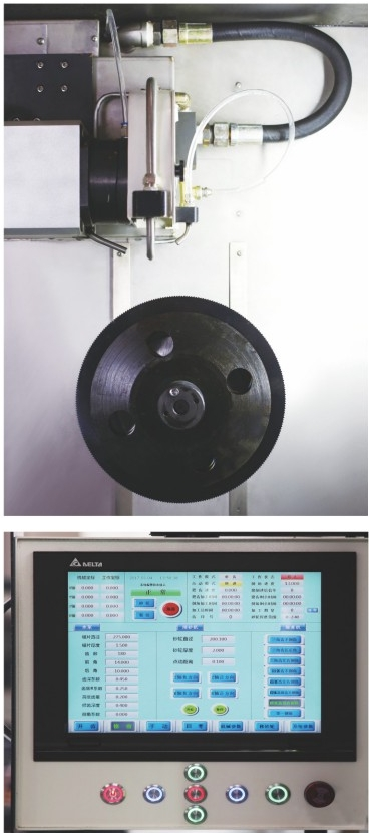

Humanized human-computer interaction interface

The input method of each parameter is simple, and the machine automatically calculates after input. No manual adjustment is required, achieving point-and-shoot operation

Intelligent tool setting system

The system has the function of automatic calculation of tool setting. After manual tool setting, the system The system automatically records the tool setting position, realizing one-button start of continuous tooth opening.

FNC-650 Intelligent Grooving System

Five-axis FNC-650 Add automatic slotting function on the basis of four axes, Now one-button start, automatic slotting; use Italian imported pneumatic motor, Higher precision and stable performance.

Ingenious details

*Drive: Delta series servo motor

*Servo reducer: Taiwan Guangyong backlash ≤ 1 arc minute

*Grinding wheel motor: Hanli customized waterproof high-precision high-speed adjustable motor

*Motion guide mechanism: adopts Taiwan Hiwin P -level precision, ZB Grade preloaded linear guide , Taiwan TBI C3 Grade precision, P2 grade pre-pressed ground ball screw

*Spindle bearing: Japan NSK-P4 Angular contact bearings

*The cooling water pump adopts a multi-stage high-pressure and large-flow plug-in water pump

* Lubrication: Use fully automatic timed oiling system

*Equipped with a powerful magnetic separator to automatically clean the grinding wheel dust

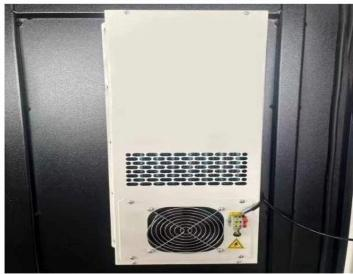

*Install a heat exchanger in the distribution box to prevent the electrical appliances from aging too quickly due to high temperature environment

* The vertical design is more suitable for saw blade grinding. The grinding machine cavity that is in contact with water should be made of stainless steel as much as possible to prevent corrosion.

*The main motion spindle is isolated from water, which greatly increases the service life

* The water tank is designed in layers to avoid excessive accumulation of grinding wheel dust. The water tank can be pushed and pulled for easy water changes.

* The top is equipped with a defogger fan for effective heat dissipation and defog (optional)

The entire inner cavity is made of stainless steel

Distribution box heat dissipation device

Automatic sand cleaning and push-pull water tank

Oil fog point Leave Device ( Can select match )

Oil fog point Leave Device ( Can select match )

Contact: Lily Tang

Tel: 0086 13812228944

E-mail: info@baolisaw.com

Add: Jinglin Industrial Park ,Jinling East Road ,Danyang City,Jiangsu Province, China